Search This Supplers Products:Road safety productstraffic signsolar traffic signsolar road studssolar signs

Vehicle detectors the installation instruction

time2017/07/05

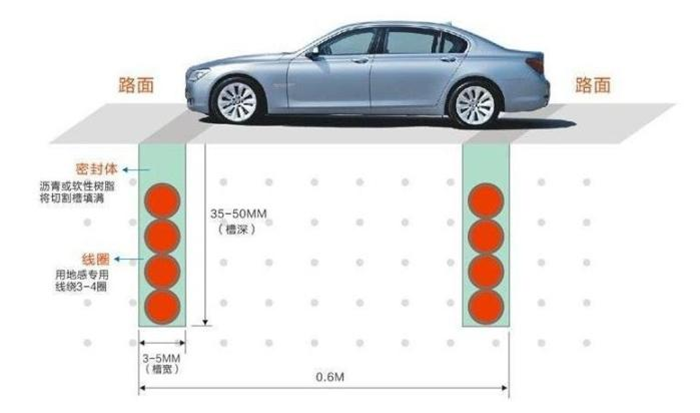

First:Detection loop installation instructions |

1, generally used in high-temperature copper ring detection, cross-sectional area of 0.5-1.5mm2. |

size |

turms |

size |

turns |

1.5mX1m |

6 |

3.5mX1m |

5 |

2.0mX1m |

6 |

4.0mX1m |

5 |

2.5mX1m | 6 | 5.0mX1m | 4 |

3.0mX1m | 5 | 6.0m above | 4 |

Second, set the sense coil turns

Sense coil circumference | Sense coil turns | ||

3 m below |

According to the actual situation, to ensure that the inductance values between 100uH-200uH to |

||

3-6 meters | 5-6 turns | ||

6-10meters | 4-5turns | ||

10-25meters | 3turns | ||

25 m above | 2turns | ||

Third, the sense coil buried method